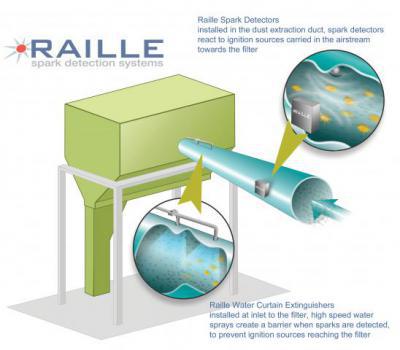

Dust extraction systems are used in many industries to remove waste material from the process machinery. Likewise, bulk handling conveyors are used to transport raw materials to each stage of the process. Both are also effective routes for sparks, embers and burning material to be carried to dust extraction filters, cyclones and storage silos where conditions may be ideal to ignite a fire or explosion.

Access to these enclosed spaces is often restricted and a fire, once started, may be difficult to extinguish. Transport ducts, clean air return ducts and interconnected conveyor networks can allow the fire to quickly spread to other areas of the factory.

Spark detection and extinguishing systems prevent ignition sources passing through a dust extraction duct and prevent fires passing through a bulk handling conveyor. Typical applications include:

- wood based panel production

- dust extraction from woodworking machinery

- dust extraction from printing, book binding and packaging

- wood pellet and biomass production and handling

- materials recycling facilities and energy from waste

- food, brewing and animal feed production

- metal smelting and casting

- dust extraction from welding cells

Highly sensitive detectors react to the infra red light emitted by hot particles moving through their field of view. The detectors must be capable of effectively monitoring the entire cross section of the duct or conveyor, while it is running and carrying a high load

of material, so sensitivity and response to all viable ignition sources is important, as is correct positioning of the components.

spark detection systems react to ignition sources

high speed reaction is activated downstream

extinguish without interrupting production

When sparks are detected, an automatic high speed reaction is activated further downstream to extinguish, isolate or otherwise suppress the hazard. The most common reaction is a curtain of high pressure water, sprayed into the path of the spark. Correctly specified and positioned, such extinguishers need only spray a small amount of water for a few seconds and so are suitable for most materials and processes. In particularly water sensitive areas, mechanical gates can be used to divert or trap the sparks, with gas, foam or powder to extinguish them once isolated.

Raille provides a comprehensive design and installation service for spark detection systems, together with

operator training, spare parts and maintenance support to help ensure continued reliable operation.

Benefits include a significant improvement in plant safety and reduction in insurance risk, together with prevention

of the costs and lost production time caused by filter fires and dust explosions.